|

|

Overview

|

|

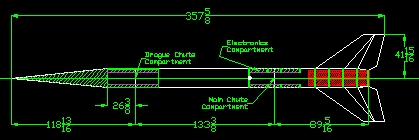

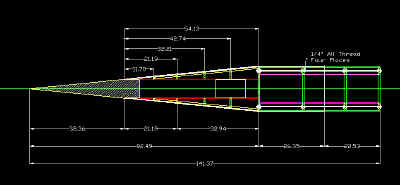

Overall length of 30 feet long with an 18.5"

diameter airframe. |

|

Powered by three 6" "P" motors,

totaling 163,800 Newton-Seconds. |

|

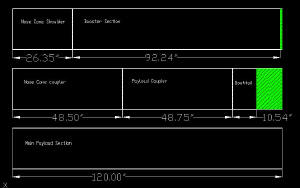

Airframe will consist of three parts, the nose cone,

upper payload section, and the lower booster section. |

|

Recovery will be dual deploy, with a 27 foot drogue

chute, then deploying a 47 foot main parachute. |

|

|

|

|

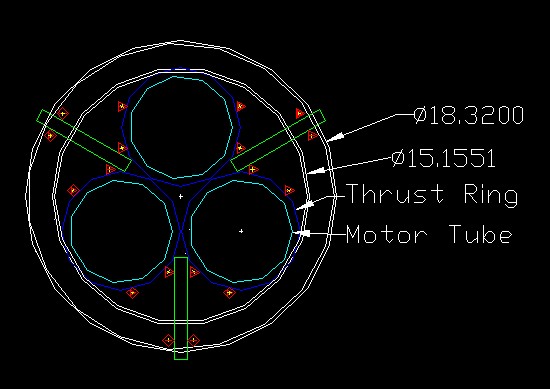

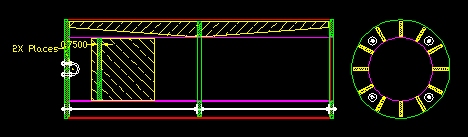

The engine mount will be

an "open frame" design. This design will utilize centering rings

only, and no motor tubes. This is need to prevent heat buildup

within the motor tubes. It will also allow for thermal expansion of the

motors during flight. |

| Currently five centering rings will be

used along the length of the motors, and will be made from 3/4"

birch plywood. |

| The structure of the motor

mount will be maintained by locking the rings in place with both

the fins and several lengths of all thread. |

| There will be a total of 18 pieces of 5/16" all-thread running the length of the motor. |

| There will be be four pieces of all-thread

used for each motor. Two pieces will be

used for motor strength/retention only. The other two pieces will be shared

between motor strength/retention and fin anchoring. Two additional pieces of all

thread will be placed at the body tube to fin tab

junction (see fin description for additional details). |

|

|

|

| UPDATED 11/28/03 |

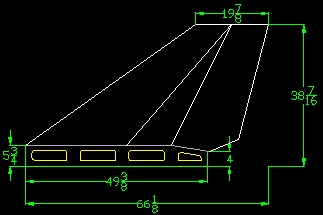

| Current fin design calls for the fins to be cut from

three pieces of 1/4" birch plywood. A full size center section,

along with two backing plates. |

| Once the core material is created, the fins will

be built-up using "Blue Foam" to give them the

scale shape, and then covered in three layers of carbon fiber. |

| For a complete description showing each layer of

the fins check out the fin layer page. |

| Four pieces of all-thread will run the length

of the fin tab. Two pieces will retain the bottom of the tab, and also be shared for motor retention.

Two other pieces will be placed on either side of the fin at the intersection of

the body tube. |

|

|

|

|

Fiberglass pipe was originally discarded as the

main airframe material due to it's high cost. After doing some

preliminary stress analysis fiberglass pipe is back in the

running. This material is being considered because of the

following criteria:

- High Strength

- Strong recommendation from Neil McGilvray

- Published design data, allowing accurate calculations rather than guess.

- Simpler construction and finishing.

|

|

18 inch diameter "Sonotube" laid up with

three layers of composite (carbon fiber, Kevlar & glass) has

been ruled out. |

|

|

|

| The nose cone will be built starting with an all

fiberglass section for the tip. This nose cone is being manufactured

and donated to the project by Performance

Rocketry. |

| The central core of the nose will be made from

7.5" PML tube covered in two layers of 10.0 oz glass. |

| Centering rings will be cut from 1/2" birch

plywood. |

| 1/4" plywood ribs will run the length of the

nose cone. |

| The ribs & rings will then be sheeted with

fiberglass strips cut from the airframe material for the first 2/3 of

the nose and PML 11.41" tube strips for the forward most 1/3. |

| A final layer (sealing layer) of glass will then

be applied to the entire nose. |

| The nose cone shoulder will be made in a same

manner as the coupler tubes. |

|

Click HERE for 3D

Solids modeling of the nose cone

|

Coupler Design

|

| Sections of the airframe be cut to form the couplers. |

| Two tube sections will be used for each coupler, with airframe tube

as the outer tube, and glassed 11.41" PML tube for the inner

tube. |

| 1/2" Rib structure will be built between the two tubes. |

| Four pieces of 1/4" all thread will run the length of each

coupler. |

|

|

Structural Design

|

| Some initial requirements for the strength of the airframe. These

requirements, and the way they were determined are detailed here. |

|

|

|

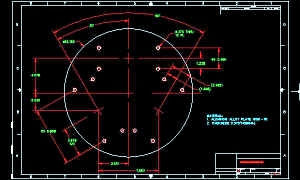

| The forward plate will be the main thrust plate and all thrust should

be centered on that. The four bolt holes per motor will transfer the

thrust from the plate, down the sides of the rocket to each of the

centering rings. |

| Click for AutoCAD Drawing |

|

|

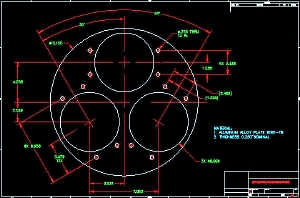

| The aft plate will provide a solid surface for motor retention. |

| Click for AutoCAD Drawing |

|

|